Drill manufacturer kicks off debate with claim their seed row spacing is best

Which is best? What is the ideal drill spacing?

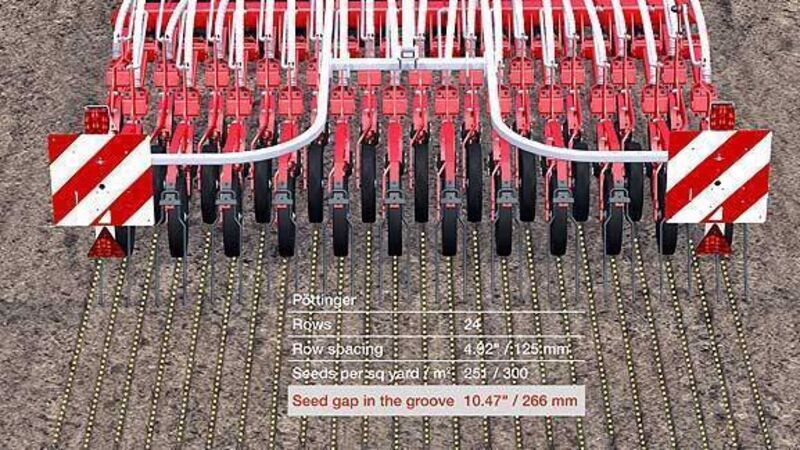

That is the question posed for debate by Austrian farm manufacturer Alois Pˆttinger Maschinenfabrik, which makes drills with a 12.5cm spacing.