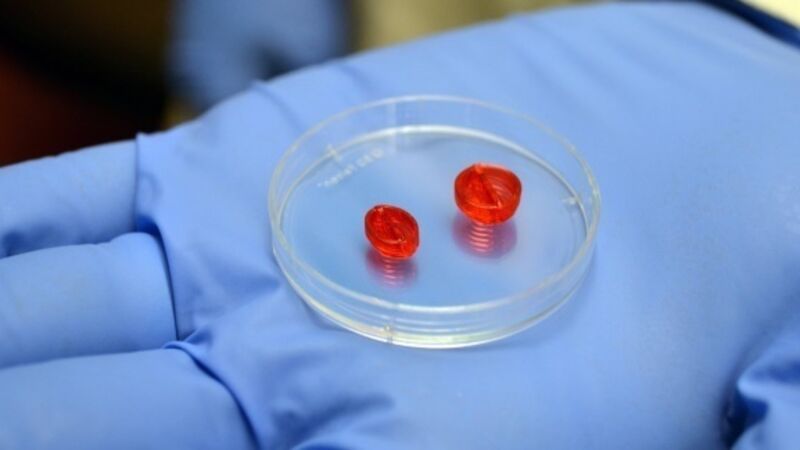

Scientists trying to use 3D printer to build human heart

Ultimately, the goal is to create a new heart for a patient with their own cells that could be transplanted.

It is an ambitious project to first make a heart, then get it to work in a patient, and it could be years — perhaps decades — before a 3D printed heart would be put in a person.