New spreader technology to improve fertiliser efficiency

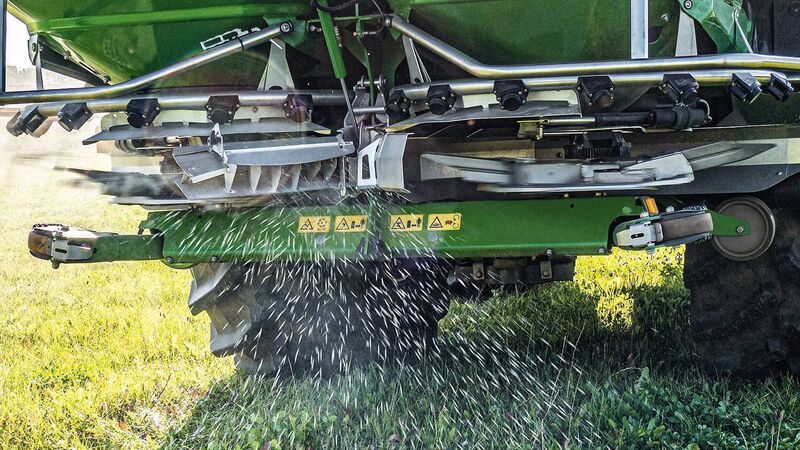

When activated, Amazone’s BorderTS deflector on the ZA-TS is swivelled into the spread fan from above. Picture: Amazone

Try from €1.50 / week

SUBSCRIBENew technology unveiled by machinery manufacturer Amazone will reduce the amount of fertiliser wasted on unproductive areas, such as field boundaries, without the hassle of leaving the cab.

The BorderTS deflector for the ZA-TS mounted spreader and the ZG-TS trailed spreader can be activated to prevent boundary spreading without stopping or slowing down.

Already a subscriber? Sign in

You have reached your article limit.

Annual €130 €80

Best value

Monthly €12€6 / month

Introductory offers for new customers. Annual billed once for first year. Renews at €130. Monthly initial discount (first 3 months) billed monthly, then €12 a month. Ts&Cs apply.

Newsletter

Keep up-to-date with all the latest developments in Farming with our weekly newsletter.

Newsletter

Keep up-to-date with all the latest developments in Farming with our weekly newsletter.

Newsletter

Sign up to the best reads of the week from irishexaminer.com selected just for you.

Newsletter

Keep up with stories of the day with our lunchtime news wrap and important breaking news alerts.

Saturday, February 7, 2026 - 9:00 PM

Saturday, February 7, 2026 - 9:00 PM

Saturday, February 7, 2026 - 12:00 PM

© Examiner Echo Group Limited